IRT KilnMonitor can use thermal cameras for different purposes:

·The thermal camera can be used both as a primary scanner and instead of a pyrometer to monitor shadow zones. A line on the image is selected which will be the source of data for scanning the kiln surface.

·The thermal camera can be used to monitor the temperature of the burning zone.

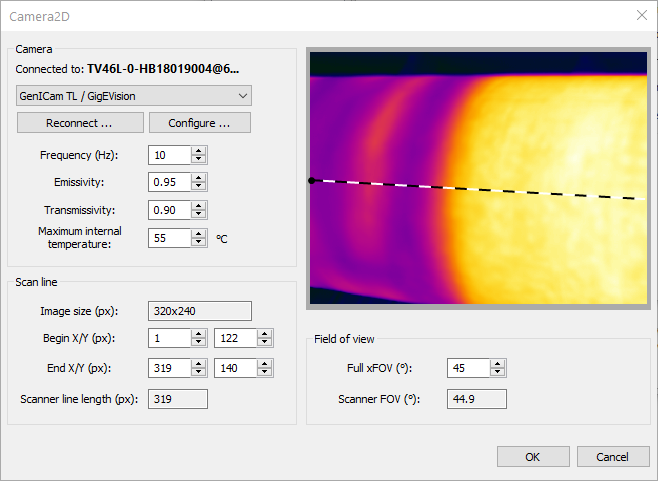

Configuration settings are the same in both cases, in the first case you must also select the scanning line:

Frequency: scanning frequency in Hz (or frames per second).

Emissivity: the kiln shell usually have surface with high emittance, so emissivity value should be around 0.95.

Transmissivity: this parameter is used to compensate thermal radiation losses because of atmospheric absorption.

Maximum internal temperature: if the specified temperature value is exceeded, a system state alarm is generated.

Scan line: the source for scan data. You can change the line by clicking on the image. First click will set the begin position, second - the end. The line begin is marked with the black dot.

Field of view: enter the horizontal field of view of the camera which will allow to calculate scan line field of view.