We present a basic concept of how brick and coating thickness estimation works. The actual algorithm is more complex and requires a calibration process to estimate unmeasured kiln parameters, such as heat loss due to convection.

Calculations are based on two equations, one for heat radiation, the other for heat conduction:

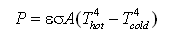

Heat radiation:

P is radiated power; A is radiating area; ε is emissivity; σ is Stefan’s constant = 5.6703*10-8 watt/(m2K4); Thot is temperature of the radiator; Tcold is temperature of the surroundings. |

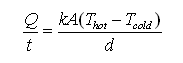

Heat conduction:

Q is heat transferred in time t; k is thermal conductivity; A is area; T is temperature; d is thickness.

|

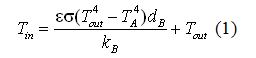

Formula to calculate temperature inside the kiln (used during calibration), assuming there is no coating and brick thickness is known:

Tin is temperature inside the kiln at light-up;

Tout is kiln shell temperature;

TA is ambient temperature;

dB is initial brick thickness;

kB is thermal conductivity of brick.

Brick and coating thickness formulas

Assumptions:

·The calibration procedure has been performed, so the internal temperature is known.

·The kiln's internal temperature remains relatively consistent throughout the entire production run, or the operator consistently updates temperature values in the system.

·The internal temperature is relatively stable within each refractory zone.

·The growth in kiln shell temperature is a result of brick wear, while a reduction in temperature is attributable to the build-up of coating.

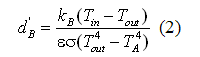

Formula for brick thickness calculation (with no coating):

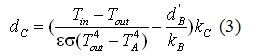

Coating thickness calculation, when brick thickness is known:

Algorithm for brick and coating thickness calculation

Formula (2) is employed to determine the actual brick thickness at each point on the scanned kiln shell. If the newly calculated brick thickness is smaller than the previously determined value, the system concludes that there is no coating and the brick is wearing out. Conversely, if the calculated brick thickness surpasses the thickness known from prior revolutions, the system infers that coating is accumulating. Once the brick thickness is established, formula (3) is be used to compute the coating thickness.

To mitigate random errors, the brick thickness map is not updated immediately. Instead, a weighted average between recently calculated values and previously stored values is utilized:

d = (1 - k)d + kdlast

d is the updated value in the brick thickness map;

dlast is the newly calculated brick thickness value;

k is the averaging weight, value is taken from Linescano.ini:

[THICKNESS]

accumulation_coefficient = 0.1

Important For the brick estimation method to work properly it is important to run calibration at the beginning of each production campaign. |