Protected by Level 1 password.

The system cannot directly measure the thickness of the bricks. Instead, it estimates the thickness by observing the temperature on the kiln shell. Therefore, our algorithm needs calibration at the start of each production campaign when the kiln is just reworked and the actual brick thickness within each refractory zone is known, either through measurement or estimation during a physical kiln inspection. The system will utilize the brick thickness data input during calibration, in conjunction with the kiln's state, as a reference point to predict changes in brick and coating in subsequent operation.

Before proceeding with the calibration, ensure that the internal kiln temperatures are correctly set. If temperatures remain constant throughout the whole production campaign, this step is not necessary. However, if temperature changes are expected, you should keep these values updated - both before and after the calibration, updating them as soon as any changes occur.

IRT KilnMonitor will notify the operator that calibration is required by showing a message in the toolbar.

For precise calibration, it's essential to conduct the procedure under appropriate conditions:

1.The kiln has been recently serviced, and you have knowledge of the actual brick thickness in each brick zone.

2.There is no coating present within the kiln.

3.The kiln has been fully heated and is operating under standard production load.

4.The weather conditions are normal: no occurrences of heavy rain, snow, or strong winds.

IRT KilnMonitor isn't capable of verifying these conditions, thus the responsibility falls on the operator.

Calibration procedure

To begin thickness measurement calibration, click on the "Kiln calibration required" message. Alternatively, you can perform the calibration at any time, even in the absence of this message, by selecting Thickness Measurement Calibration from the Configuration menu.

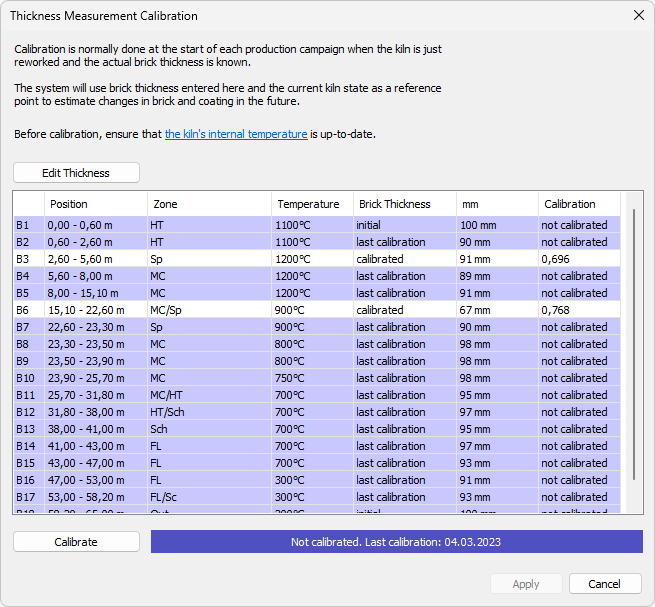

Start by clicking the Edit Thickness button to enable the editing mode. Then, proceed through all brick zones, inputting the actual brick thickness for each zone. If a zone isn't new and the thickness varies within it, input the average thickness. If you're unsure of the actual thickness in a zone, you can choose one of the recent thickness values provided by the system, selecting the one you believe most accurately reflects reality.

The recent thickness values options include:

·Initial: The new brick thickness from the refractory configuration.

·Last calibration: The thickness set during the previous calibration of this zone.

·Estimated: The thickness predicted by the system at this kiln position during the previous campaign.

·Drilling: The result from drilling in this area.

IRT KilnMonitor does not reset the calibration for brick zones where parameters have remained unchanged, assuming no alterations occurred during refractory rework. These zones are displayed in the list as "calibrated". If you need to recalibrate them, simply input the actual thickness (or select "changed" from the thickness dropdown menu). If you leave the thickness unchanged and the zone is marked as calibrated, IRT KilnMonitor will not recalibrate it.

To compute calibration parameters, click the Calibrate button. All zones marked as not calibrated will be recalibrated using the brick thickness indicated in the list. Note that at this stage, the new calibration has not yet been saved in the system. To save and implement the new calibration, click the Apply button.