Kiln design normally includes external rings (tires) that support the kiln hull. Rings are not fixed to the kiln and have a slightly bigger than the kiln diameter. Rings are not rotated – kiln rotates the rings. Because of temperature change inside the kiln, kiln diameter varies. If kiln diameter becomes bigger than the ring diameter, the ring will damage the kiln. Rings diameter should be all the time bigger than the kiln diameter.

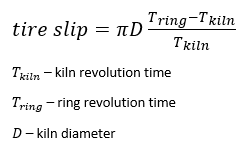

Tire slip is the difference between kiln circumference and ring circumference (measured in millimeters or inches).

IRT KilnMonitor includes monitoring system (TSM), that measures tire slip for each ring and generates alarms when measured values exceed defined limits.

Tire slip monitoring system needs sensors that generate signals every time a ring makes full rotation. When the kiln or a ring makes a full rotation, the system gets a signal from the kiln trigger sensor or a ring sensor, so that kiln and ring rotation time is known and can be compared. IRT KilnMonitor calculates tire slips of all rings and generate alarms if calculated values are out of the predefined range. Alarm is also generated if we have not got the signal during the period of maximum kiln rotation time.

Configuration

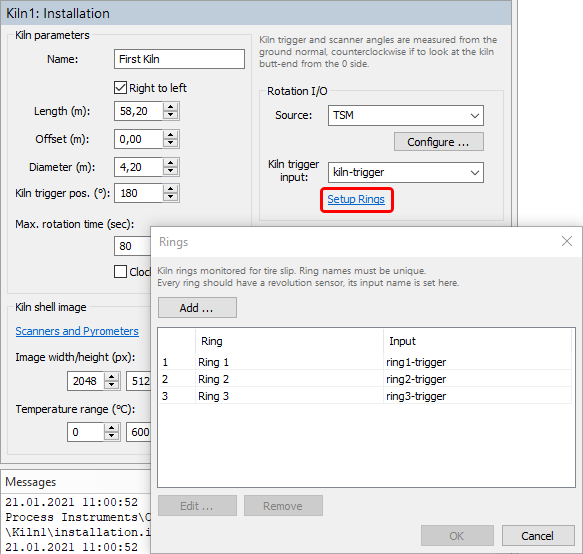

You need to define the rings and select I/O device inputs used for each ring. This is done on the Installation page:

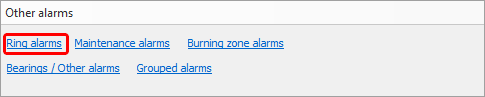

To define allowed tire slip limits for each ring, go to the Alarms page, Other alarms window:

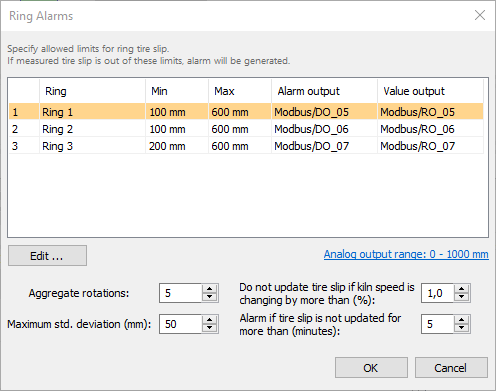

Tire slip value measured by one revolution may not be accurate enough. To improve the accuracy IRT KilnMonitor averages values from several kiln revolutions.

Aggregate rotations: number of revolutions that are used to measure tire slip value more accurately.

Maximum std. deviation: allowed standard deviation for values measured at each revolution. Number of revolutions for standard deviation calculation is defined by Aggregate rotations parameter. If standard deviation exceeds the allowed value, ring alarm is generated.

Varying kiln rotation speed

If kiln rotation speed is not constant, measured tire slip values will be inaccurate and cannot be used to trigger alarms.

Do not update tire slip if kiln speed is changing: percent value of acceptable kiln rotation speed change. Current revolution time is compared to the average revolution time measured from N last revolutions, where N is the Aggregate rotations parameter. If rotation speed change is too big, tire slip value is not updated.

Alarm if tire slip is not updated: because of changing kiln rotation speed current tire slip value can stay without updates for long time. This parameter allows to generate ring alarm if its tire slip value was not updated for too long.

False ring sensor signals

False ring sensor signals are filtered using the same method as the kiln trigger signal is filtered. The same setting in Linescano.ini are applied to both kiln trigger and ring sensor signals. Please see False kiln trigger signals description for details.