Protected by Level 2 password.

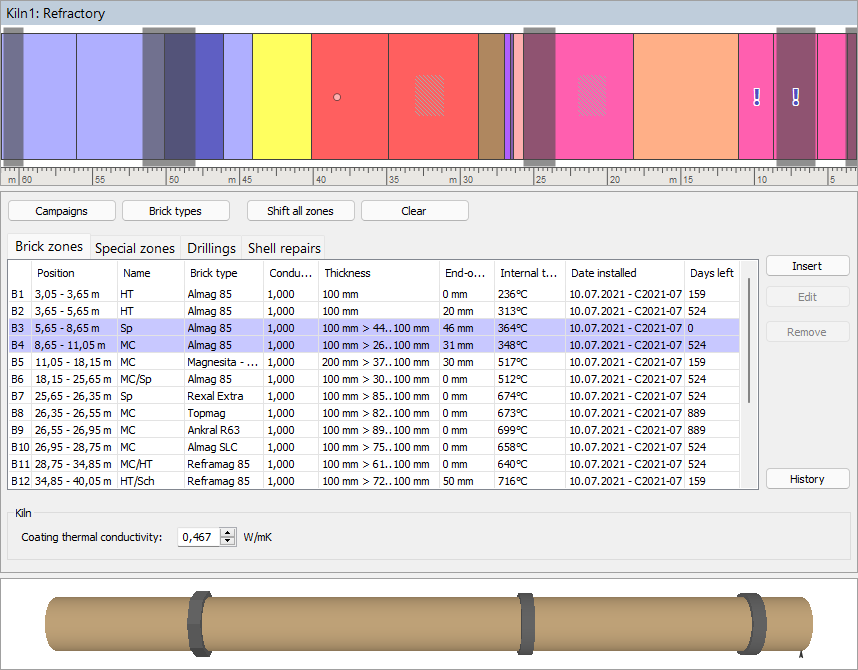

Information about bricks is used to calculate brick and coating thickness during kiln monitoring. It also allows IRT KilnMonitor to create a graphical diagram of the kiln refractory zones. It is important to keep the refractory information up-to-date.

Select Refractory item in the tree structure at the left part of the Configuration window. Before you can define refractory zones, kiln dimensions on the Installation page must be defined. See topic Kiln dimensions and monitoring hardware.

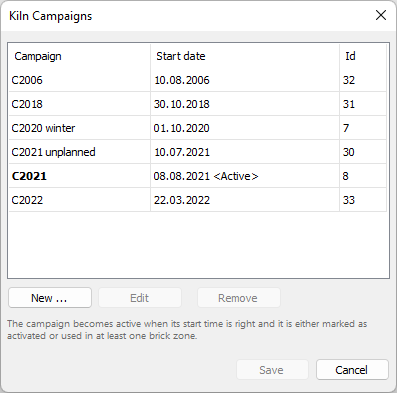

Kiln campaigns

Campaign is the time of kiln operation between maintenance stops. Campaigns are mainly needed to improve the structure of refractory history reports.

Refractory brick zones are replaced during kiln maintenance stops, before a new campaign starts. This way every brick zone is linked to a campaign.

IRT KilnMonitor allows to change refractory zones without creating a new campaign. This possibility should only be used to correct wrong entries if mistakes have been made. |

Press Campaigns button to show the list of campaigns.

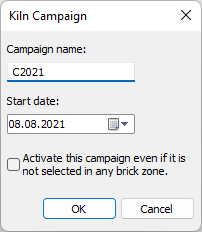

For a campaign you need to specify a name of the campaign and a start date. The campaign start date will also be used as the installation date for brick zones installed at the beginning of this campaign.

It is safe to change the campaign start date. This will automatically modify installation date of the brick zones linked to this campaign and recalculate brick life time.

A campaign becomes active when its start time is right and it is either marked as activated or used in at least one brick zone. |

Brick types

Press Brick types button to show the list of all available brick types. This list is for convenience only, so you don't have to enter the same data multiple times.

It is possible to import bricks from a CSV file. The format of the file is fixed:

UTF-8; separated by comma

Columns:

1.Manufacturer (text)

2.Name (text)

3.Material (text)

4.Thermal conductivity (W/mK)

5.Thickness (mm)

6.Zone color (number R+(G*256)+(B*65536) )

7.Description (text)

8.Brick life (days, optional)

9.Minimum thickness (mm, optional)

Brick zones

To show the list of all brick zones, select Brick zones tab:

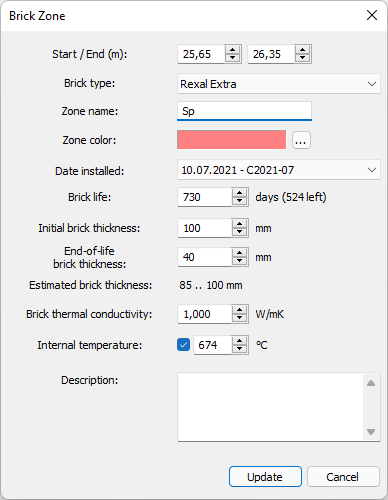

Use the Insert button to add new zone definitions to the kiln refractory. For every zone you can specify different parameters depicted below. To modify already existing zone, double-click on it or select it and press Edit. To remove a zone, mark it in the refractory window or in the list of zones and press the Remove button.

In case a new or a modified zone overlaps some existing zones, the existing zones will be automatically sized or deleted.

Every brick zone has the following parameters:

·Start/End position along the kiln axis;

·Brick type: type of the brick used in the zone;

·Zone name;

·Zone color: color to display the zone in the kiln design view;

·Date installed: link to the campaign when this brick zone was installed;

·Brick life: typical working time of bricks in this zone;

·Initial brick thickness: working thickness of a new brick;

·End-of-life brick thickness: thickness limit, if brick becomes thinner than this limit it must be replaced (Refractory alarm);

·Estimated brick thickness: actual brick thickness estimated from the temperatures measured on the kiln shell;

·Brick thermal conductivity: usually ranges from 0,1 to about 10 W/mK;

·Internal temperature: temperature inside the kiln at this zone. If internal temperature is not known, remove the mark in the check box.

·Description: any text description you may need.

Note Brick conductivity, internal temperature and initial brick thickness are important for proper estimation of brick and coating thickness. In case the internal temperature is not specified (no check in the check box), brick thickness estimation algorithm will try to estimate the internal temperature by using the average kiln shell temperature in this zone (inaccurate). |

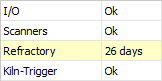

Brick life and Refractory alarm

Date installed and Brick life parameters are used to control typical brick duration. When bricks in one of the refractory zones reach the end of their typical life cycle, the Refractory alarm is generated and corresponding brick zones are marked with an exclamation mark.

Refractory pre-alarm is displayed 30 days before the end of the brick's typical life.

30-day period can be changed in Linescano.ini configuration file:

; if remaining brick life is less than this value, pre-alarm will be generated. Set to 0 to disable pre-alarm.

brick_life_prealarm_days = 30

Refractory alarm is also activated when estimated brick thickness is smaller than the End-of-life brick thickness.

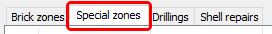

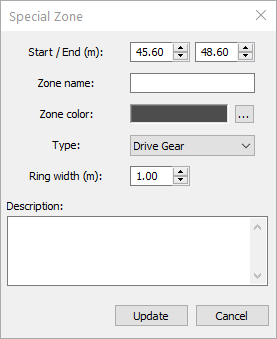

Special zones

Special zones are needed to mark the areas of the kiln where brick thickness calculation is not possible because these areas are blocked from scanners and pyrometers view.

For special zones, beside location, name and color, you can define zone type ("Gear Rim", "Live Ring" or "Other") and ring width.

Zone type and ring width is used to display corresponding “ring” on the 3D kiln model. There are no 3D display for special zones with type "other".

Note Special zones are excluded from brick and coating thickness calculation (using the Start/End position) as they do not allow scanners to measure temperature on kiln surface in these zones. |

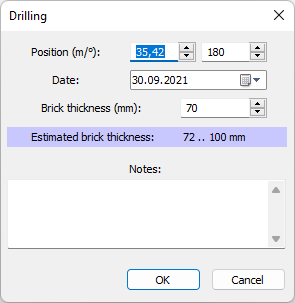

Drillings

This list is used to register kiln drillings. Data from this list does not affect system functioning.

Brick thickness: the actual brick thickness that was measured when drilling (entered by the operator).

Estimated brick thickness: brick thickness of the brick zone at the drilling position estimated by IRT KilnMonitor.

The two values - actual and estimated - should usually be similar. If they are very different, this means that parameters for the brick thickness estimation algorithm (such as the bricks thermal conductivity or the temperature inside the kiln) are set up incorrectly.

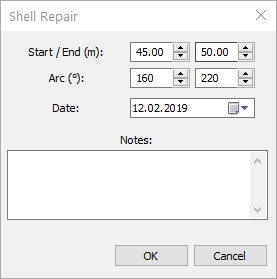

Shell repairs

This list is used to record places of the kiln where shell repairs were made. Data from this list does not affect system functioning.

Whole kiln related controls

Use Shift all zones button to shift all brick and shadow zones along the kiln right or left by a specified value. Shift value is added to start and end position of each zone. To make a left shift, enter a negative value.

Pressing Clear button deletes all refractory zones - brick zones, special zones, drillings and shell repairs.

At the bottom of the window, you can set Coating thermal conductivity used for calculation of coating thickness. (Clinker conductivity is about 0.467 W/mK for 0-700°C, and it increases above 700°C). The same value is used at any part of the kiln.